Additional Fabrication

In addition to my engineering coursework, Baja, and my co-op, I enjoy taking fabrication classes and working on personal projects. Here are some of my favorites.

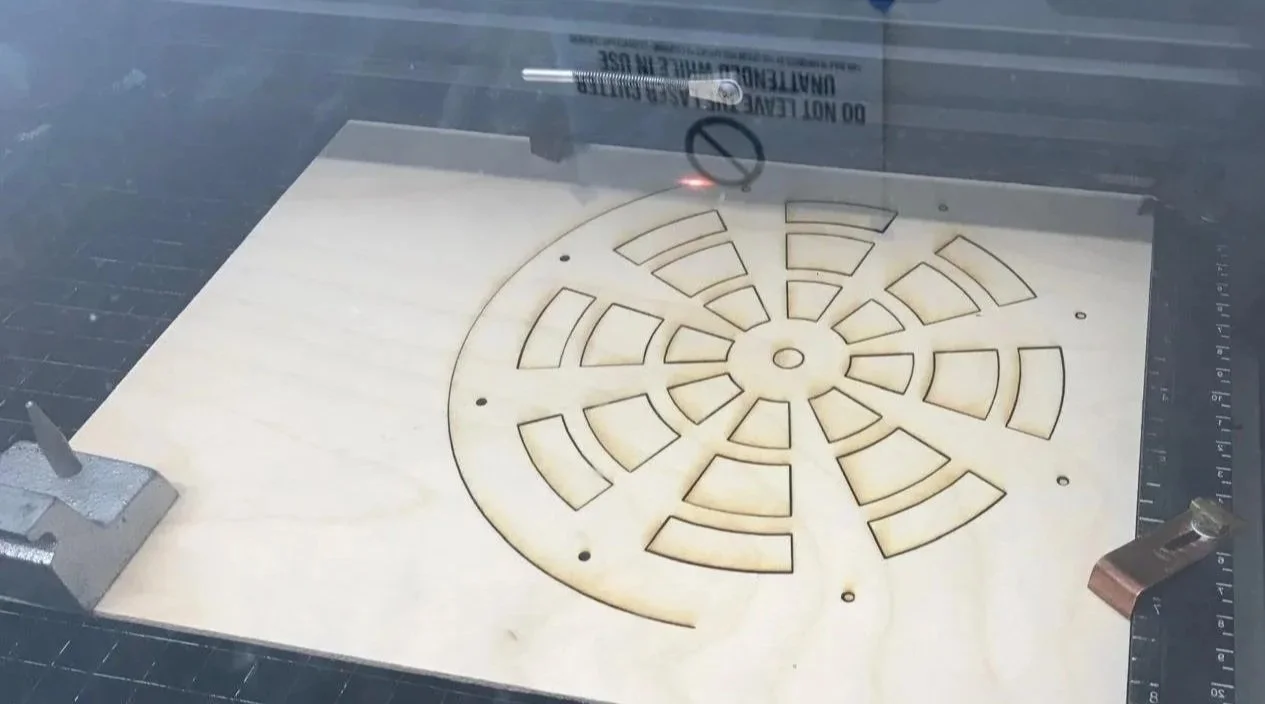

Laser Cut Ferris Wheel

Objective: Design, laser cut, and assemble a 3D ferris wheel model that can rotate and does not require any adhesive.

For this project, I created CAD models in SolidWorks and used SolidWorks Assemblies to ensure proper fitment. Then I created SolidWorks Drawings, and imported those drawings into Adobe Illustrator. I used a laser cutter along the Illustrator vector drawings to cut each piece from plywood. After some experimentation with tolerances, I successfully assembled the ferris wheel without adhesive.

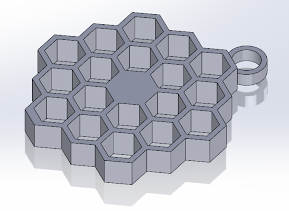

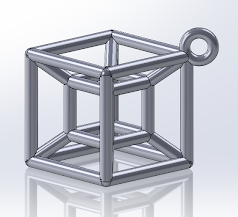

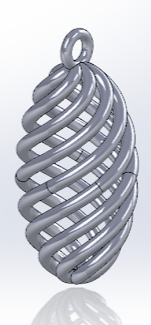

3D Printed Earring Series

Objective: Create a set of three pairs of earrings, each modeled in SolidWorks and 3D printed. Each earring design increases in expected modeling difficulty and uses different CAD tools.

I created this project with the goal of learning SolidWorks. The first pair of earrings, inspired by JWST’s mirrors, was chosen so I could learn how to create sketches and extrude. The second pair of earrings, the spirals, was chosen so I could learn how to make a circular pattern and sweep. The last pair, the hypercubes, was chosen so I could learn how to create a shape that was 3D but not just one extruded shape. Then I 3D printed each pair of earrings on the Prusa MK3S printer, learning how to use supports and troubleshoot the multiple problems that arose.

Tensegrity Table

Objective: Create a two-piece table where the top piece is suspended and stabilized by the tension in the chains.

This was a fun project. I started with a CAD model to choose my angles and dimensions, and then used woodworking tools to manufacture and assemble the table. I learned the basics of working with glass for the two triangle windows, went through a lot of trial and error for the number of rings on each chain, and eventually came up with a product I’m really proud of.

Parallel Clamp

This parallel clamp is made from aluminum and threaded steel rods. I cut both jaws and my name using a programmable ProtoTRAK 2-axis CNC mill. Then I cut the threaded rods and knobs to length on a lathe, and knurled the knobs. Then I assembled the clamp, and have since used it multiple times in the machine shop!

Deadblow Hammer

This deadblow hammer is made primarily from aluminum, then filled with steel BBs, and the two caps are made form plastic. I turned the handle, head, and caps on the lathe. Then I experimented with the BBs to find a weight that minimized bounce back. I press-fit the plastic caps into the aluminum head.